Welding is a fascinating and rewarding craft that requires skill, precision, and attention to detail. Whether you are an experienced welder or a beginner looking to hone your skills, mastering the art of welding stainless steel with flux core is a must. In this guide, we will explore the ins and outs of welding stainless steel with flux core welder from selecting the right equipment and materials to executing the perfect weld.

We will also discuss the benefits and drawbacks of flux core welding stainless steel and provide you with tips and techniques for achieving high quality welds. So, let’s get started and discover the secrets to the art of welding stainless steel.

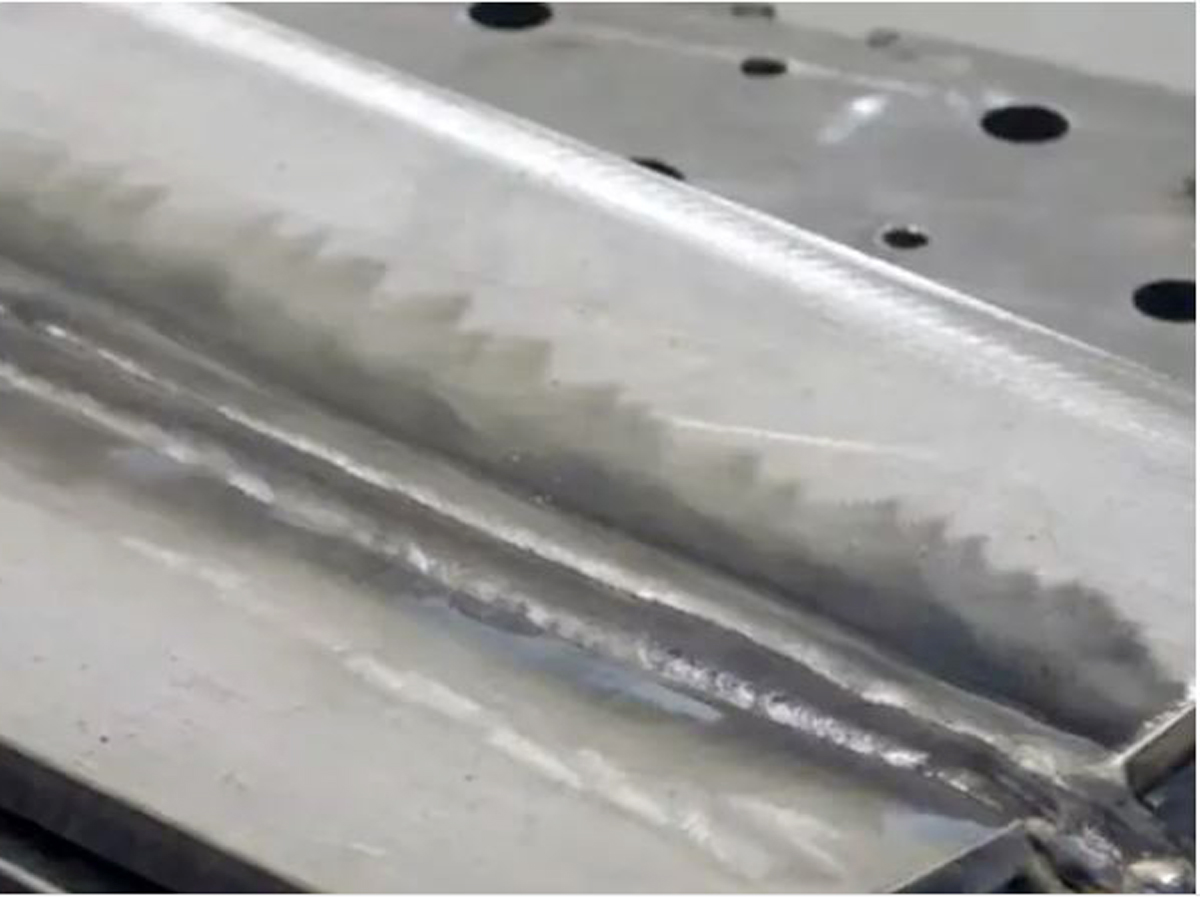

Photo Welddotcom

Basics of Welding Stainless Steel with Flux Core

Welding stainless steel with flux core is a process that involves using a wire with a flux core that melts and shields the weld. It’s a popular technique because it’s versatile, easy to learn, and suitable for a wide range of applications. To get started with welding stainless steel with FCAW, you need to understand the basics of the process.

The first step is to select the right welding machine for your needs. Flux core welding requires a machine that can deliver a constant voltage, which means that a MIG welder is the best option. You will also need to choose the right wire for your project. Stainless steel flux core wire is available in a range of diameters, and you will need to select the right size for your project.

Once you have the right equipment and materials, you need to prepare your workspace. Make sure that your work area is clean and free of any debris that could interfere with your weld. You should also have a fire extinguisher on hand in case of an emergency.

Benefits of Welding Stainless Steel with Flux Core

Welding stainless steel with flux core has many benefits. One of the biggest advantages is that it’s a self-shielding process, which means that you don’t need to use an external shielding gas. This makes it an ideal technique for outdoor welding or when working in areas with poor ventilation. Flux core welding produces less spatter than traditional welding techniques, which means that you will spend less time cleaning up after your weld.

Another benefit of welding stainless steel with flux core is that it can be used to weld thicker materials than traditional MIG welding. This makes it a great option for projects that require welding thicker metal plates or pipes.

Equipment and Materials for Welding

To weld stainless steel with flux core, you will need the following equipment and materials:

- A MIG welder

- Stainless steel flux core wire

- Welding gloves

- Welding helmet

- Welding jacket

- Welding pliers

- Chipping hammer

- Wire brush

Make sure that you have all of these items before you start welding.

Safety Precautions When Welding Stainless Steel with FCAW

Welding stainless steel with flux core is a safe process as long as you take the necessary precautions. The first step is to make sure that you are wearing the appropriate safety gear, including a welding helmet, gloves, and jacket. You should also make sure that your work area is well ventilated to prevent the buildup of fumes. When welding stainless steel, you should also be aware of the risk of electric shock. Make sure that your welding machine is properly grounded and that you’re not touching any metal surfaces with your bare skin. You should also avoid welding near flammable materials and always have a fire extinguisher on hand.

Preparing Your Workspace for Welding Stainless Steel with Flux Core

Before you start welding stainless steel with flux core, you need to prepare your workspace. Start by cleaning your work area and removing any debris that could interfere with your weld. You should also make sure that your welding machine is set up properly and that your wire is feeding correctly. Once your workspace is ready, you can start welding.

However, before you begin, it’s important to do a test weld to make sure that your equipment is set up correctly and that your wire is feeding properly. This will help you avoid any issues later on and ensure that you get a high-quality weld.

Techniques for Welding Stainless Steel with Flux Core

Welding stainless steel with flux core requires a specific set of techniques. The first step is to select the right wire speed and voltage for your project. This will depend on the thickness of the material you are welding and the diameter of your wire.

Once you have set up your machine, you can start welding. Begin by positioning your torch at a 90-degree angle to the workpiece and making a tack weld to hold the pieces in place. Then, move your torch along the joint, keeping your wire at a consistent distance from the workpiece.

As you weld, make sure that you’re maintaining a consistent speed and that you are not overheating the metal. You should also be aware of the risk of porosity, which can occur if you’re welding too quickly or if your wire is feeding too slowly. To avoid porosity, make sure that you re using the right wire speed and voltage for your project.

Advantage of Welding Stainless Steel with Flux

Welding stainless steel with flux has several advantages over traditional welding techniques. The first advantage is that it’s a self shielding process, which means that you don’t need to use an external shielding gas. This makes it an ideal technique for outdoor welding or when working in areas with poor ventilation.

Another advantage of welding stainless steel with flux is that it produces less spatter than traditional welding techniques. This means that you will spend less time cleaning up after your weld and that you will be able to get a cleaner, more precise weld.

Disadvantage of Welding Stainless Steel with Flux

While welding stainless steel with flux has many advantages, it also has a few disadvantages. The biggest disadvantage is that it can produce more slag than traditional welding techniques. Slag is a byproduct of the welding process that can interfere with the quality of your weld. To avoid slag, make sure that you are using the right wire speed and voltage for your project.

Tips for Achieving High Quality Welds

To achieve high quality welds when welding stainless steel with flux, there are a few tips that you should keep in mind. The first tip is to make sure that your equipment is set up correctly and that your wire is feeding properly. You should also be aware of the risk of porosity and slag and take steps to avoid these issues. Another tip is to maintain a consistent speed and distance from the workpiece as you weld.

This will help you avoid overheating the metal and ensure that you get a clean, precise weld. It’s important to practice your welding skills regularly. The more you practice, the better you’ll become, and the easier it will be to achieve high-quality welds.

Continuing to Improve Your Welding Skills

Welding stainless steel with flux core is a challenging but rewarding process that requires skill, precision, and attention to detail. By following the tips and techniques outlined in this guide, you will be able to master the art of welding stainless steel with flux core and take on more challenging projects. Remember to always prioritize safety, select the right equipment and materials, and practice your welding skills regularly. With dedication and practice, you’ will be able to achieve high- quality welds that will stand the test of time.